- INDUSTRY

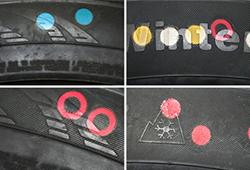

- AUTOMOTIVEENGINEERINGCABLES, WIRES, EXTUSIONSFOODCHEMICAL AND PHARMACEUTICALPACKAGINGCONSTRUCTIONRUBBER

LASER MARKING

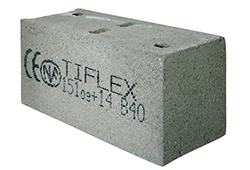

DOT PEEN MARKING

AUTOMATION

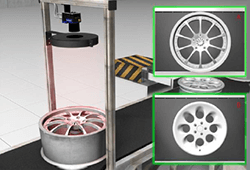

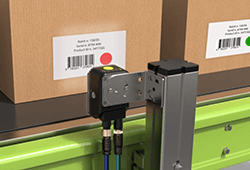

MACHINE VISION

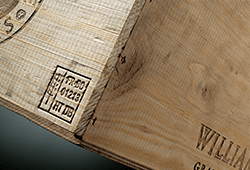

LASER MARKING

DOT PEEN MARKING

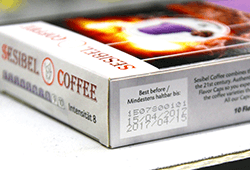

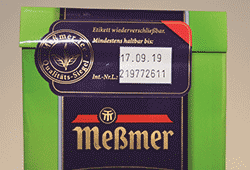

THERMAL TRANSFER

MACHINE VISION

INK MARKING

LASER MARKING

HOT STAMPING

MACHINE VISION

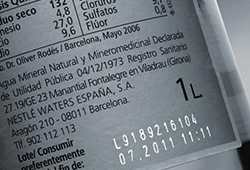

INK MARKING

HOT STAMPING

THERMAL TRANSFER

LASER MARKING

INK MARKING

LASER MARKING

THERMAL TRANSFER

MACHINE VISION

THERMAL TRANSFER

INK MARKING

LASER MARKING

MACHINE VISION

THERMAL TRANSFER

INK MARKING

LASER MARKING

MACHINE VISION

INK MARKING

LASER MARKING

HOT STAMPING

MACHINE VISION

- INDUSTRY

- PRODUCTS

- LASER MARKINGINK MARKINGDOT PEEN MARKINGTHERMAL TRANSFERAUTOMATIONMACHINE VISIONHOT STAMPING

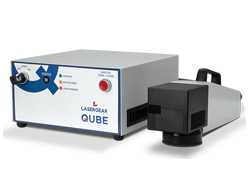

Qube

Vereo

Vereo Smart

AREX

V-LASE

ALL DEVICES

alphaJET mondo

alphaJET into

U2 Pro

HRP R4

HRP R32

ALL DEVICES

DOT PP

DOT P+N

DOT U

DOT N

DOT P

ALL DEVICES

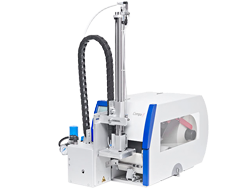

DuoPrint

Micra

APL 100

ttPRINT Inline

ttPRINT Multiline

ALL DEVICES

Standardised workstations

Workstations

Machine vision

hdpSystem nano

hdpSystem vario

hdpSystem magno

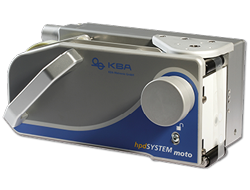

hdpSystem moto

- PRODUCTS

- SERVICES

- CONTACT

- LIFTEC CZPocernicka 272/96

108 03 Praha 10

Czech RepublicLIFTEC SKZlatovska 2415/33B

911 05 Trencin

Slovak RepublicE-mail: liftec@liftec.euCONTACT US

Tel: +421 32 7430 850

-

- CONTACT

- ABOUT US

PROPERTIESMODELSPARAMETERSACCESSORIESVIDEO

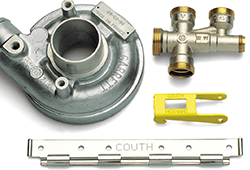

Reliable and durable micro-impact marking suitable for marking metal and hard plastic – pedestal type.

MC 2000 is a reliable solution for permanent micro-impact marking. The pneumatically or electrically driven micro-impact marking machine that uses high frequency and precisely located micro-dots for printing a wide range of characters, shapes, 2D codes, images etc. stored in memory, in the required dimension and intensity.

Micro-impact marking can be used for almost any material (metal, plastic, wood, glass etc.). The highly resistant and well-visible marking can also be used prior to material finish or coating. This system can be used to mark extremely hard, uneven and irregular, flat and bent products that are not deformed or excessively stressed thanks to the option of precise setting.

The long-lasting durability, maintenance-free operation and easy integration into production lines, without the need for a PC connection, makes this an unparalleled tool for durable product marking.

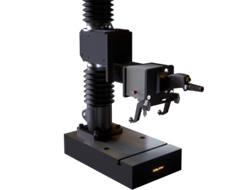

Properties DOT N

A pedestal-type system with a clamping table. Marking smaller products in larger batches, manual or semiautomatic operation. Engraving option.

ADVANTAGES OF MICRO-IMPACT MARKING

- Highly durable marking visible under a layer of paint or other surface finish

- Contact marking without additional costs, does not require any consumables

- Large marking area of up to 250 mm x 170 mm

- Controlled micro-impact value ensures quality and fast marking

- Engraving option – cursive writing, marking does not make noise

- A wide range of characters from 0.125 mm up to 20 mm of character height

- Marking in any position of the marking head

- Efficient software for message design in the control unit or on a PC

- Possibility to print 2D Datamatrix codes, logos, graphic symbols and images

- A wide range of accessories for easy integration and for increasing marking efficiency

(rotary clamping, pneumatic marking head approach, micrometric clamping, label feeder etc.) - Control unit with a large display showing the message in real size and shape

- Integrated serial RS232 and Ethernet communication, also available Profibus, Profinet and Ethernet/IP

- Autonomous control system, no computer required for operation

MC 2000 N – Pedestal-type system with a clamping table

Marking smaller products in larger batches, manual or semiautomatic operation.

(engraving option)

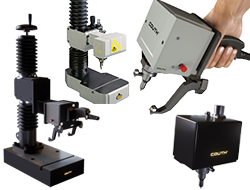

MC 2000 U – System for integration

Suitable for production lines, robotic arms etc. (engraving option)

MC 2000 P – Manual

Mobile marking for large, unusual products or products that are difficult to manipulate with

MC 2000 P+N – Combined manual/with a table

For marking batches as well as unusual products or products that are difficult to manipulate with

Dimensions of the marking areas of standard micro-impact equipment

50×17 (50×25), 100×17 (100×25), 160×17 (160×25), 90×60, 150×100

Dimensions of marking areas of equipment for additional charge

170×170, 250×60, 250×100, 250×170

Dimensions of the marking areas of micro-impact equipment for deep marking

72×35, 200×35

Dimensions of the marking areas of engraving equipment

75×15, 80×80, 180×45