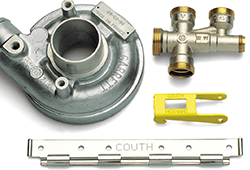

Automated Marking of Aluminium Parts

February 2018

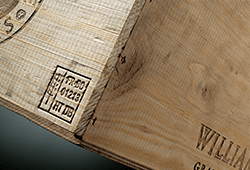

Aluminium Parts Marking Project

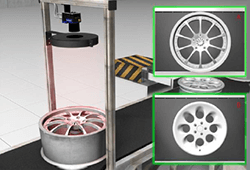

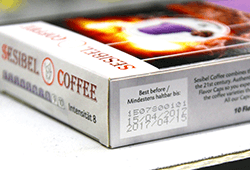

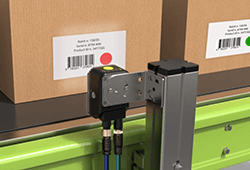

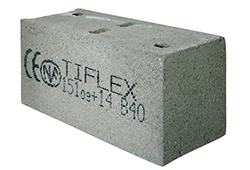

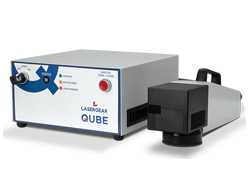

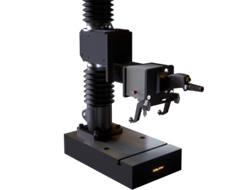

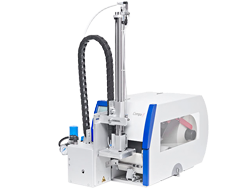

Many manufacturers in the engineering industry require automatic marking. One of our customers approached us with an inquiry about marking aluminium parts. The worked aluminium castings were to be marked, in a permanent manner, with a 2D code, which was then checked and sent to the customer’s host system. Then, it was required to distinguish among several production parts and each mark with a proper code. We created a workstation with a four-position carousel table onto which the operator manually places parts and takes them away. The operator inserts the part and only presses the start button without having to select a program or complicated settings. The station moves the product into the area of the camera where the part is identified and a corresponding 2D code is automatically selected. When another part is inserted, it is moved to a position where the laser is installed. The laser provides the 2D code marking as it knows what part and what code is required based on the information from the camera. When another part is inserted, this part moves into the area equipped with a reader where the 2D code is checked and registered in the system. Another inserted part moves this part to the area of the operator who takes it away. Thanks to the carousel conception, marking and check occur at the time when the operator inserts or takes away the parts, which minimises any downtime, thus making production more efficient and providing large cost savings.