FAQ

FREQUENTLY ASKED QUESTIONS

This page contains the most frequently asked questions about the industrial marking technology.

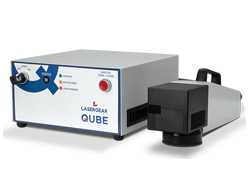

LASER MARKING

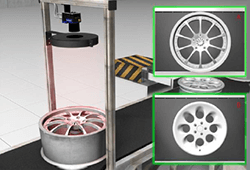

How to choose suitable laser marking?

It is important to choose a suitable laser marking technology when selecting the marking laser. It needs to be determined what material will be marked, what marking speed is required, or whether marking will be applied to a static object or a moving product on a production line belt or conveyor. Then, we choose from industrial lasers: CO2 laser marking technology, fibre or DPSS (solid state) lasers in relation to the physical properties of the material to be marked. CO2 – laser marking is used mostly on softer material, such as paper, cardboard or softer plastic. Fibre laser marking is used for printing on metal and harder plastic material. We recommend consulting the selection of suitable laser marking with our experts.

What safety measures need to be followed in laser marking?

Since industrial marking lasers are devices dangerous for human sight (laser equipment class 4), it is required to follow the prescribed occupational safety rules. Therefore, covered workstations – workstations with protective safety elements are used in static laser marking applications. Special goggles with a filter against laser radiation, according to the wavelength and type of jet, are required for maintenance and service. The laser marking workstation has to be visibly marked with safety elements in the form of self-adhesive labels and tags.

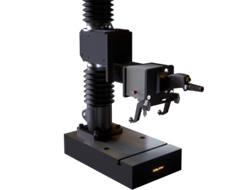

MICRO-PERCUSSION MARKING

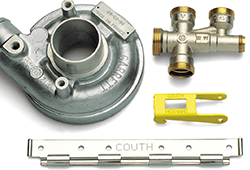

What materials can be marked with micro-engraving or micro-percussion?

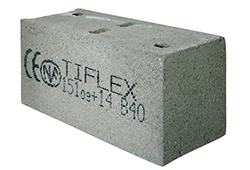

The micro-percussion technology is designed for industrial marking of all hard, not fragile and not very flexible materials such as metals, plastic, wood or hard leather.

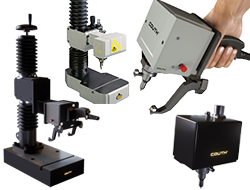

What are the basic types of micro-percussion devices?

In principal, there are two types of devices: for micro-percussion – i.e., marking using individual points created by percussion, or there are devices that combine the option to perform micro-percussion and pressure engraving with a sharp and hard tip.

Can this technology be used on varnished or powder-coated products?

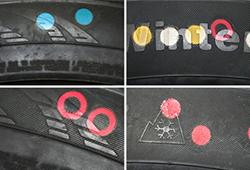

Yes. The experience shows that it can also be used for marking varnished sections and metal pipes. As the marking is deep, it can penetrate paint. It can be used for marking data matrix codes that can be subsequently checked with a reader.

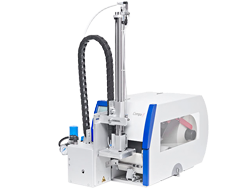

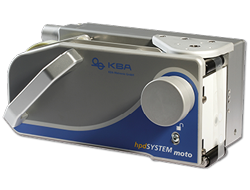

INK-JET PRINTERS

What is the difference between the ink-jet technologies for printing small and large characters?

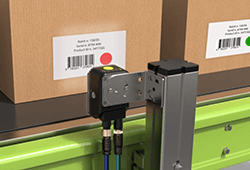

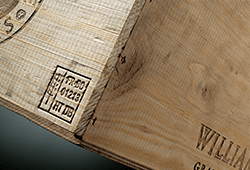

The basic differences in those ink-jet technologies is the method of application. Ink-jet marking of small characters (INK-JET CIJ) enables printing directly on the product or packaging, which can be both non-absorbent and absorbent. The ink-jet print consists of small droplets that allow for miniature letters. The ink-jet technology for large character printing uses considerably larger droplets with a rougher raster. It is mostly used on group cardboard packaging and product marking.

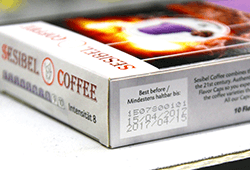

What can be marked with the small character ink-jet print?

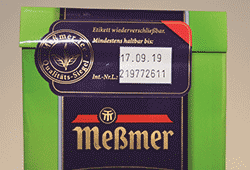

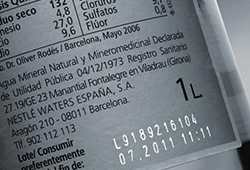

You can mark using alphanumerical characters, such as production date and expiry date, batch, product numbering, simple signs and symbols, or more complicated printing messages containing text, numerical characters and also bar codes or other 2D codes.

What principle does the CIJ (Continuous Ink Jet) technology uses?

Simply said, the technology uses continuous (continuously circulating) ink jet made in the ink system by diluting the main printing medium – ink using a solvent. The printing is then done by deflecting the ink jet consisting of ink droplets, charged with an electric charge. The small character ink-jet printing is done by combining the individual ink droplets into the injection of the whole message within the defined matrix.

What inks can be used?

The continuous small character ink jet technology (CIJ) allows for marking products using a wide range of standard and special industrial inks with specific properties. Darker shades are suitable for light surfaces and vice versa, lighter pigment inks are suitable for darker surfaces – the pigment particles improve contrast and legibility.

What is the average ink drying time?

The standard drying times of industrial inks take seconds. The fastest drying inks for CIJ are based on quickly evaporating substances, such as acetone and butanone, which ensures that they dry within 2 seconds. They are mostly used in industrial branches with a large production volume and speed where the print must not be smudged or removed in the following process. The print achieves the final properties after curing or ageing, which is in 24 hours similarly to other fast-drying paints.

Is ink marking permanent or temporary?

Generally, permanent product marking includes laser, micro-percussion and engraving technologies. However, some types of industrial inks are characterized by higher resistance to removal. Therefore, they cannot be removed using common cleaning detergents, water or alcohol. Some inks are resistant to petrol or brake fluid (suitable, for example, for the automotive industry). The resistance of special inks can be improved by curing with industrial UV lamps. However, the standard mechanical resistance of most inks is sufficient for common use.