Automated Marking of Gear Parts

March 2018

Gear Parts Marking Project

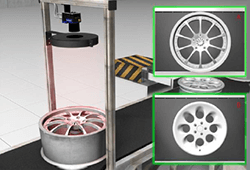

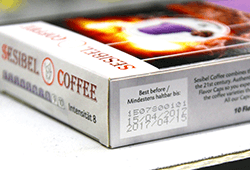

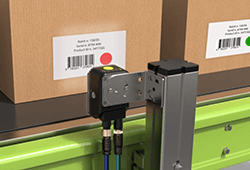

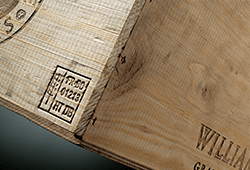

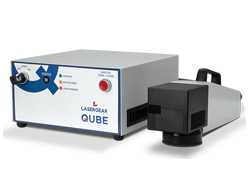

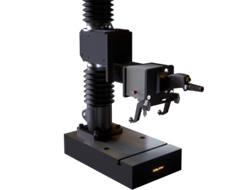

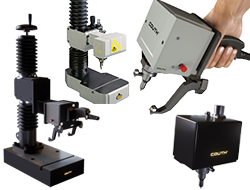

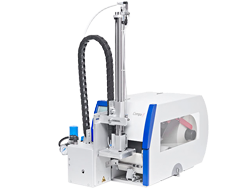

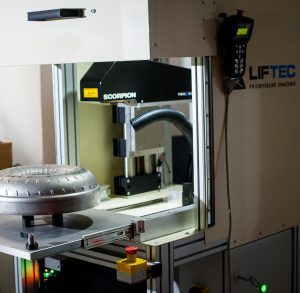

We created an integrated workstation for marking gear parts with 2D codes for a prominent engineering business that manufactures parts for the automotive industry, with high demands on product quality. One of the basic requirements was to ensure low noise level of marking, because for example a micro-impact device may create noise of up to 70 dB. We decided to work with laser as it is not only quieter, but also more precise. Another requirement was to make handling easier because this job concerned heavy and large parts that the operator manually inserts and takes away. This was provided by an extensible mechanism on which the part is placed and then inserted into the workstation to be marked. The task of marking, in this case, was to monitor the entire production process with the aim to minimise the error rate. As this method of marking is permanent, traceability across all the production operations is provided for the entire service life of the part. Moreover, the 2D code is an ideal solution for monitoring the product origin and for storing any necessary information that can be subsequently read by machine vision systems. After a successful test operation, the workstation was integrated into the production and the company subsequently ordered several other such workstations.

We created an integrated workstation for marking gear parts with 2D codes for a prominent engineering business that manufactures parts for the automotive industry, with high demands on product quality. One of the basic requirements was to ensure low noise level of marking, because for example a micro-impact device may create noise of up to 70 dB. We decided to work with laser as it is not only quieter, but also more precise. Another requirement was to make handling easier because this job concerned heavy and large parts that the operator manually inserts and takes away. This was provided by an extensible mechanism on which the part is placed and then inserted into the workstation to be marked. The task of marking, in this case, was to monitor the entire production process with the aim to minimise the error rate. As this method of marking is permanent, traceability across all the production operations is provided for the entire service life of the part. Moreover, the 2D code is an ideal solution for monitoring the product origin and for storing any necessary information that can be subsequently read by machine vision systems. After a successful test operation, the workstation was integrated into the production and the company subsequently ordered several other such workstations.