Intelligent Label Marking

April 2019

Industrial Marking 4.0

Smart Factory

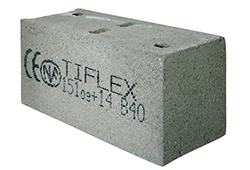

There are more and more production and logistic environments based on digital process control systems in various industrial branches. Machines exchange information with people or other machines, process data relevant for the production independently, deliver data or forward them. The key requirements are individualisation, scalability, lean and traceable processes as well as reliable devices and components.

Most applications or services that the control systems are based on are available on the Internet. The data from sensors, equipment or software are transferred to the cloud and they can be easily exchanged between the printers, robots and IT systems – provided that they all speak the same language and understand one another.

OPC UA protocol creates networks in industrial production

Open Platform Communications Unified Architecture, or OPC UA, creates the foundation for the interaction between machines and components from various manufacturers in the industrial environment. The various specifications in OPC UA were consolidated with a consistent data model to create a new standard interface. OPC UA creates networks in industrial production, similar to those we know from network and USB interfaces in offices.

Are you putting a production plant into operation? Or are you planning to network warehouses using Industry 4.0?

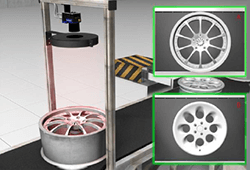

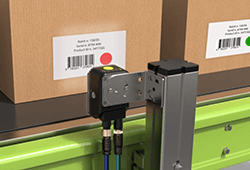

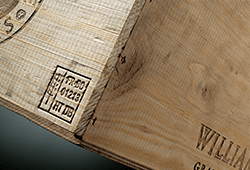

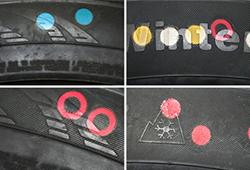

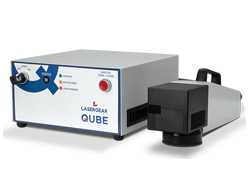

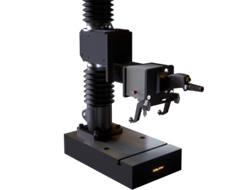

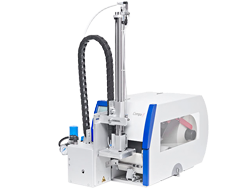

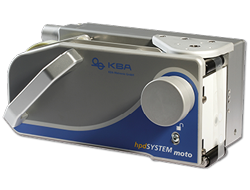

If there is an IP-ready network available, OPC UA can be used as a consistent framework for access to information among machines. In the field of marking components, products or packaging within one plant, there are current-generation CAB label printers as well as the Ixora labelling device, prepared for OPC UA. They are able to cooperate with host control units.

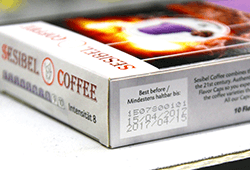

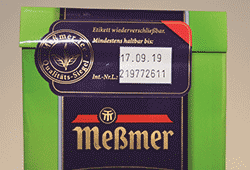

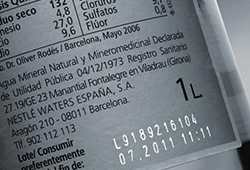

On-line label print administration

It is old-fashioned to determine the printer status by pressing a button. Today, intelligent devices automatically indicate that they need service or that the material to be printed, or the ribbon, is too short and must be replaced. It is possible to upload labels remotely, as well as to replace variable data for printing. The operating parameters, such as the print head output, its temperature or number of labels to be printed in the current roll, are displayed in the right time. The printer transfers information to the corporate management system that identifies and interprets the information and directly initiates a corresponding measure.