Workstations for Marking Connectors for Electric Cars

January 2019

Workstation for marking connectors for electric cars

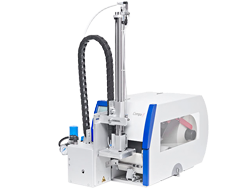

One of our latest projects includes a station for a company that manufactures components for the automotive industry. This company approached us with an inquiry about a station that would perform assembly, check and marking of connectors for electric cars. Considering the number of versions, the station was to be in the POKA-YOKE character so that it would not be possible to insert and assemble a connector from the wrong components.

One of our latest projects includes a station for a company that manufactures components for the automotive industry. This company approached us with an inquiry about a station that would perform assembly, check and marking of connectors for electric cars. Considering the number of versions, the station was to be in the POKA-YOKE character so that it would not be possible to insert and assemble a connector from the wrong components.

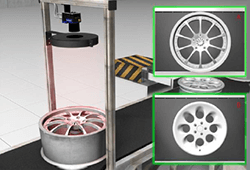

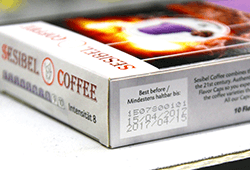

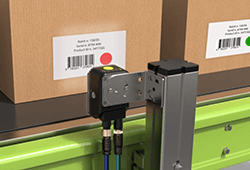

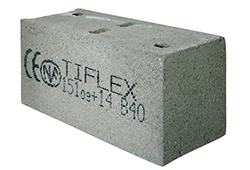

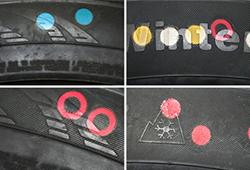

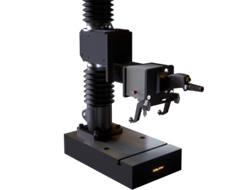

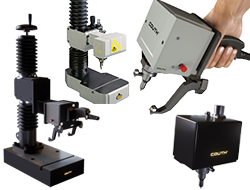

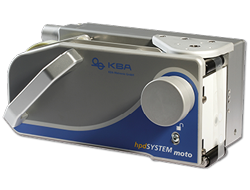

We designed a workstation with a 4-position carousel table equipped with special inserting devices that prevent the insertion of a wrong component. The components that only differ in colour are monitored by a camera. The operator inserts the individual components in the devices, the station assesses that everything is in its right place and right type. The station then reports that everything is prepared and the operator starts the cycle. The rest is done automatically. The connector is assembled and the carousel table turns by one position. There is another camera there that checks whether or not the assembly has been performed correctly. Thanks to the carousel table, the operator can insert other components at this time without having to wait for the whole process to finish. Everything is thus done efficiently and without unnecessary downtime. The next turn takes the connector to a position where it is marked using micro-impact. This method of marking is permanent, ensuring traceability of the component across all the production operations during its service life. However, marking is only done when the camera assesses that the assembly is in order. Incorrect and thus unmarked connectors are scrapped by the station in a lockable box for non-compliant products. The compliant components are transferred by a conveyor to the following operations.