- INDUSTRY

- AUTOMOTIVEENGINEERINGCABLES, WIRES, EXTUSIONSFOODCHEMICAL AND PHARMACEUTICALPACKAGINGCONSTRUCTIONRUBBER

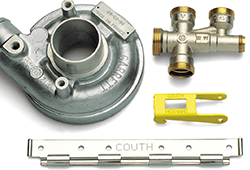

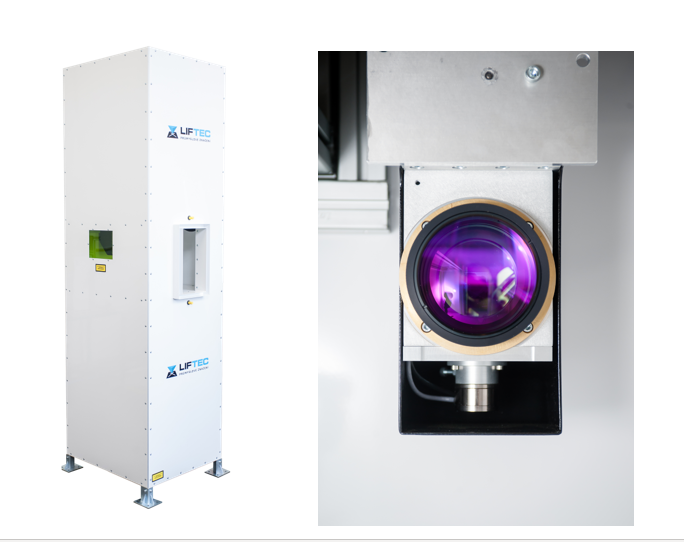

LASER MARKING

DOT PEEN MARKING

AUTOMATION

MACHINE VISION

LASER MARKING

DOT PEEN MARKING

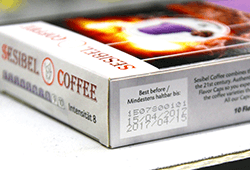

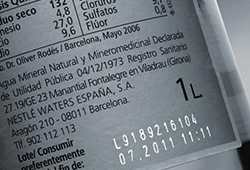

THERMAL TRANSFER

MACHINE VISION

INK MARKING

LASER MARKING

HOT STAMPING

MACHINE VISION

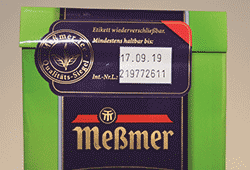

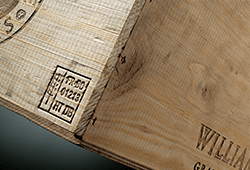

INK MARKING

HOT STAMPING

THERMAL TRANSFER

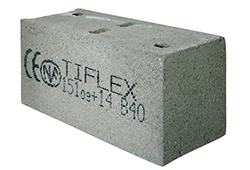

LASER MARKING

INK MARKING

LASER MARKING

THERMAL TRANSFER

MACHINE VISION

THERMAL TRANSFER

INK MARKING

LASER MARKING

MACHINE VISION

THERMAL TRANSFER

INK MARKING

LASER MARKING

MACHINE VISION

INK MARKING

LASER MARKING

HOT STAMPING

MACHINE VISION

- INDUSTRY

- PRODUCTS

- LASER MARKINGINK MARKINGDOT PEEN MARKINGTHERMAL TRANSFERAUTOMATIONMACHINE VISIONHOT STAMPING

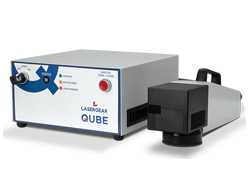

Qube

Vereo

Vereo Smart

AREX

V-LASE

ALL DEVICES

alphaJET mondo

alphaJET into

U2 Pro

HRP R4

HRP R32

ALL DEVICES

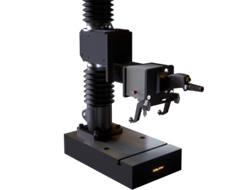

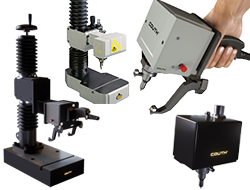

DOT PP

DOT P+N

DOT U

DOT N

DOT P

ALL DEVICES

DuoPrint

Micra

APL 100

ttPRINT Inline

ttPRINT Multiline

ALL DEVICES

Standardised workstations

Workstations

Machine vision

hdpSystem nano

hdpSystem vario

hdpSystem magno

hdpSystem moto

- PRODUCTS

- SERVICES

- CONTACT

- LIFTEC CZPocernicka 272/96

108 03 Praha 10

Czech RepublicLIFTEC SKZlatovska 2415/33B

911 05 Trencin

Slovak RepublicE-mail: liftec@liftec.euCONTACT US

Tel: +421 32 7430 850

-

- CONTACT

- ABOUT US

PROPERTIESMODELSVIDEO

Tailor-made solutions

When working with lasers, it is required to observe the necessary safety measures as well as provide sufficient user comfort, which is guaranteed by tailor-made workstations. The workstations can include, in addition to the marking equipment, machine vision, KUKA robots, individually developed software capable of creating databases or communicating with a host system.

Tailor-made workstations

- An integrated solution of the customer’s requirements for product marking, identification and monitoring

- Optimisation of the marking process efficiency in every industrial field and in any application

- Automation of all marking technologies, from inkjet through micro-impact to laser

- Custom-made software

- Optical control – machine vision

- Robotization – integration of KUKA robots

- Integration into current lines

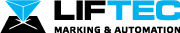

Integration of KUKA robots

The KUKA robots are integrated into the workstations or into complete workplaces. KUKA offers a wide assortment of industrial robots.

From the smallest ones with a load capacity from 3 kg, which can work in a 600 x 600 mm cell, through high-performance robots with a load capacity of 6-22 kg and reach over 2 m, to the largest ones that can manipulate parts with a weight of up to 1,300 kg.

- Six-axis robots with various load capacity and impact

- Light robots capable of direct human-machine cooperation

- Robots for automation of pressing with enormous reach for loading and unloading large parts into automated presses

- Palletising robots for fast manipulation

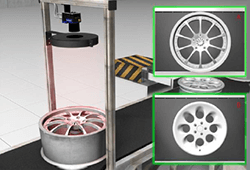

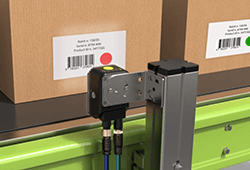

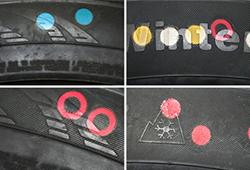

- Machine vision systems for product checks

- Intelligent solutions for production monitoring, identification and quality control.

- Cameras

- Code readers

- Scanners

- Safety gates

- Systems capable of integration

PLC programming

Since every production is specific, our software specialists develop tailor-made programs, in addition to the supplier’s software that the marking equipment comes with, for the optimisation of the entire marking process..

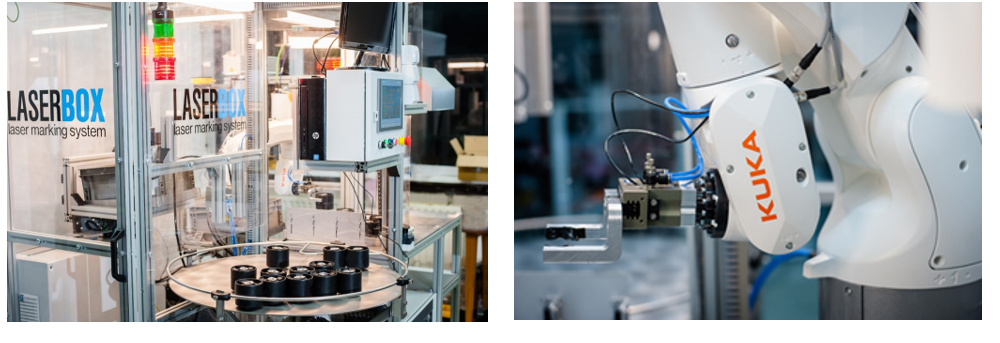

Station designed for marking printed heating elements

A carousel station designed for marking printed heating elements. The station is controlled by factory programmed software. The station also includes generation of a serial number, which is checked by the reader after marking and stored in the database.

Station cooperating with a robot

A station cooperating with a robot, designed for marking moulded plastic headlights.

Station for marking connectors

A carousel station designed for marking connectors with marking check and identification. The station is controlled by factory programmed software and it also includes OK and NOK pieces sorting.

Station for handling bushing

A robotized workstation designed for automated evaluation of the product type and its subsequent marking with a unique 2D code.