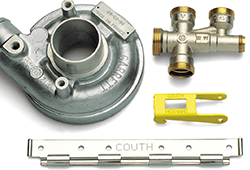

- INDUSTRY

- AUTOMOTIVEENGINEERINGCABLES, WIRES, EXTUSIONSFOODCHEMICAL AND PHARMACEUTICALPACKAGINGCONSTRUCTIONRUBBER

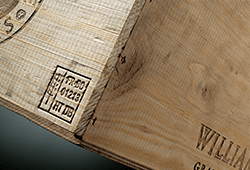

LASER MARKING

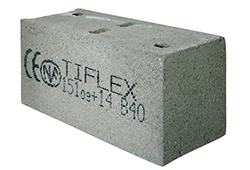

DOT PEEN MARKING

AUTOMATION

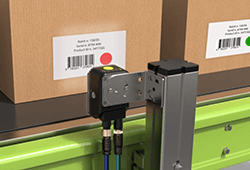

MACHINE VISION

LASER MARKING

DOT PEEN MARKING

THERMAL TRANSFER

MACHINE VISION

INK MARKING

LASER MARKING

HOT STAMPING

MACHINE VISION

INK MARKING

HOT STAMPING

THERMAL TRANSFER

LASER MARKING

INK MARKING

LASER MARKING

THERMAL TRANSFER

MACHINE VISION

THERMAL TRANSFER

INK MARKING

LASER MARKING

MACHINE VISION

THERMAL TRANSFER

INK MARKING

LASER MARKING

MACHINE VISION

INK MARKING

LASER MARKING

HOT STAMPING

MACHINE VISION

- INDUSTRY

- PRODUCTS

- LASER MARKINGINK MARKINGDOT PEEN MARKINGTHERMAL TRANSFERAUTOMATIONMACHINE VISIONHOT STAMPING

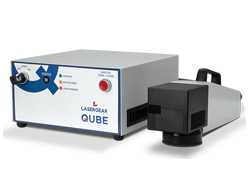

Qube

Vereo

Vereo Smart

AREX

V-LASE

ALL DEVICES

alphaJET mondo

alphaJET into

U2 Pro

HRP R4

HRP R32

ALL DEVICES

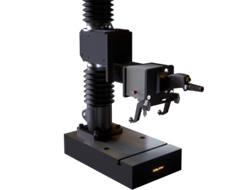

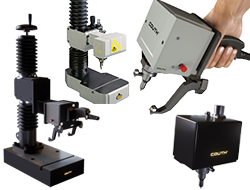

DOT PP

DOT P+N

DOT U

DOT N

DOT P

ALL DEVICES

DuoPrint

Micra

APL 100

ttPRINT Inline

ttPRINT Multiline

ALL DEVICES

Standardised workstations

Workstations

Machine vision

hdpSystem nano

hdpSystem vario

hdpSystem magno

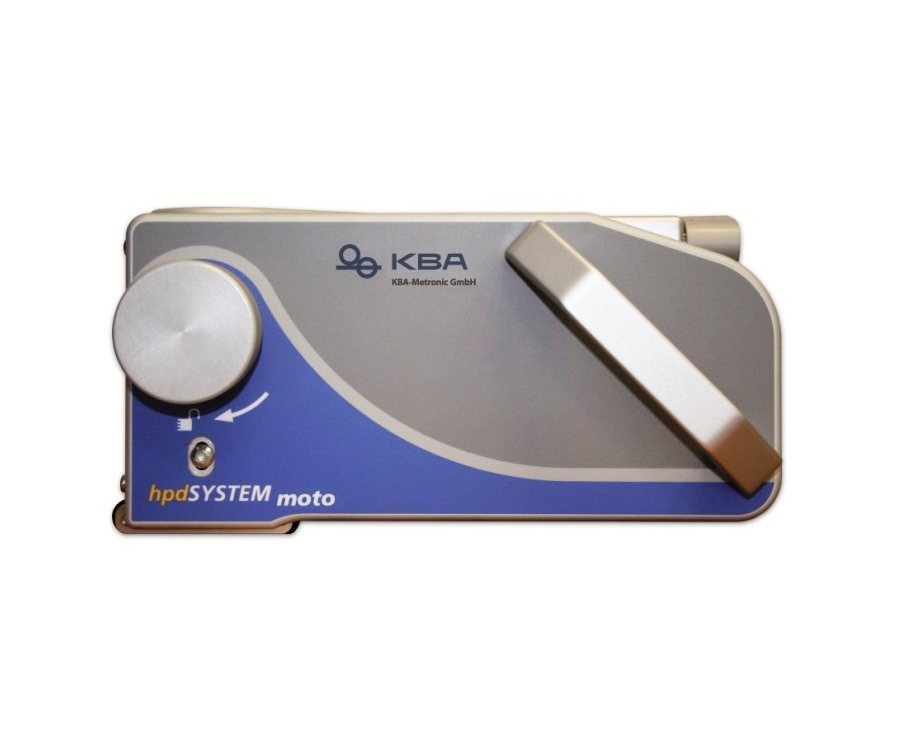

hdpSystem moto

- PRODUCTS

- SERVICES

- CONTACT

- LIFTEC CZPocernicka 272/96

108 03 Praha 10

Czech RepublicLIFTEC SKZlatovska 2415/33B

911 05 Trencin

Slovak RepublicE-mail: liftec@liftec.euCONTACT US

Tel: +421 32 7430 850

-

- CONTACT

- ABOUT US

PROPERTIESPARAMETERSACCESSORIESVIDEO

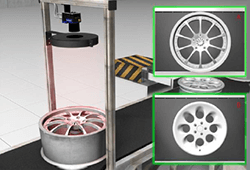

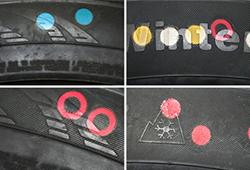

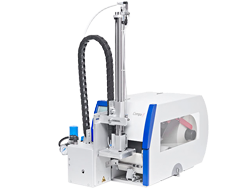

The hpdSYSTEM moto printer combines all the current standards of safety, usability, design and control. It is a hot stamping printer designed for marking tyres on testing table stations. For greater variability, hpdSYSTEM moto is manufactured in the right and left version.

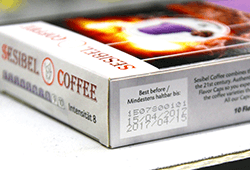

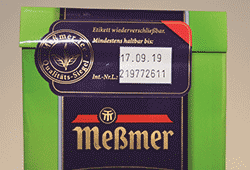

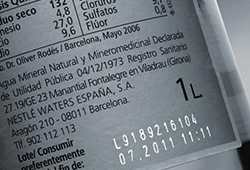

Hot stamping is a simple contact product marking method, during which the heated die prints a colour layer of hot stamping foil on the required product or its packaging. This marking system is used for various materials and it is one of the least economically demanding methods of marking your products, if you do not require printing of frequently changing data. KBA-Metronic GmbH has been involved in the production of hot stamping printers for more than 40 years and at present, they offer four systems that differ in the print frequency, print surface dimensions and possibility to implement the printer in lines.

Technical data:

Print surface

20 x 20 mm

Print output / speed

80 prints/minute (depends on the material and die)

Stamping foil

max. 305 m, ø 110 mm

Foil feed

automatic

Air pressure

580 N at 6 bar

Drive type

pneumatic

Air connection

min. 4 – max. 6 bar, ø 6/4 mm

Air consumption

approx. 0.25 l for printing (with max. shift)

Power supply

24 V DC ( ± 10% tolerance), 160 VA

Protection

IP 54

Temperature

323-473 K (50 ° – 200 ° C)

Heating capacity

120 W

Printing time

approx. 20 – 2000 ms

Function

feed protection with a reset function

Version

Right or left version

Dimensions

142 x 288 x 166 mm

![]()

Datasheet 1 hdpSystem EN

hpdSYSTEM_en.pdf (485.2 kB)

![]()

Datasheet 2 hdpSystem EN

hpdSYSTEM2_en.pdf (351.2 kB)

![]()

Datasheet 1 hdpSystem DE

hpdSYSTEM_de.pdf (487.2 kB)

![]()

Datasheet 2 hdpSystem DE

hpdSYSTEM2_de.pdf (353.8 kB)