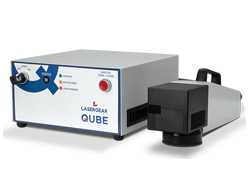

Tiskárna – U2™ DIESEL

Combining quality, efficiency and cost savings

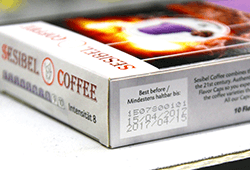

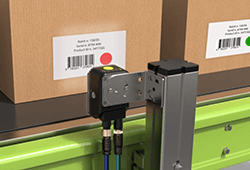

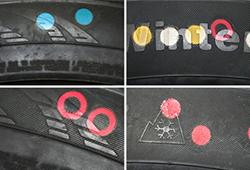

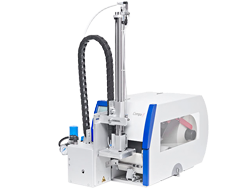

Printer U2™ DIESEL is a combination of quality, efficiency and cost savings. The ink cartridge enables printing of contrast codes on a large number of absorbent packaging material.

The TIJ printers use ink cartridges for thermal inkjet printing and do not require any ink or solvent bottles. Therefore, the use of this technology is clean, simple and desired in operations with high demands on cleanliness, such as pharmaceutical or food-processing businesses.

The thermal inkjet printers work on the principle of ejecting ink droplets from the cartridge. The ink droplets are heated to a high temperature using electric resistance. The microscopically-thin film of the printing ink is heated to the temperature of about 340°C, creating a bubble that drives the ink out. The ink droplet spurts from the bubble and prints the required area. This process is continuously repeated during the print.

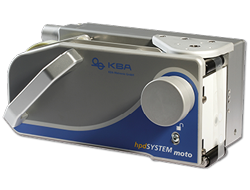

420 ml bulk ink ANSER Diesel prints 4 times darker than standard ink, which leads to 4 times higher print capacity and substantial print cost savings.

The exclusive Diesel ink formula provides a longer DECAP time of up to 60+ hours to prevent problems with cartridge maintenance, including missing lines and jet choking.

420 ml ink cartridge enables high-resolution print with better readability.

One Diesel ink cartridge is capable of printing the same number of messages as 5 litres of large-character printer ink.

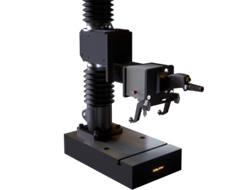

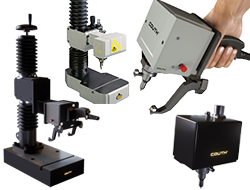

Accessories

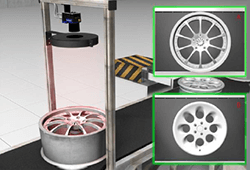

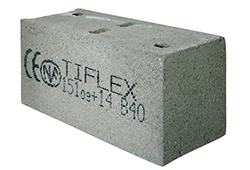

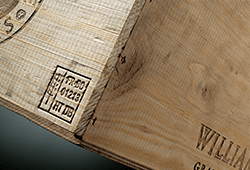

Wood marking

![]()

Letak Anser U2 DIESEL CZ

anser_U2_cz.pdf (642.38 kB)

![]()

Poster Anser U2 DIESEL EN

anser_U2_diesel_en.pdf (3.22 MB)