Off-line marking technology

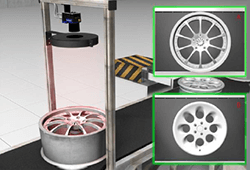

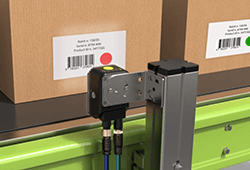

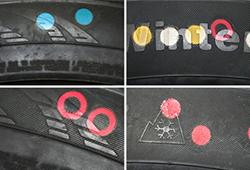

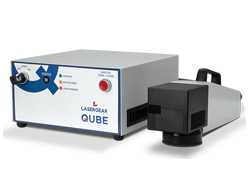

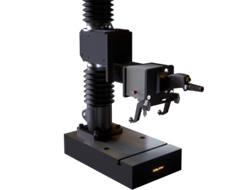

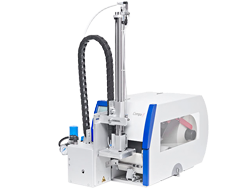

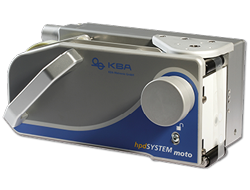

Off-line marking technology LIFTEC offers the UdaFORMAXX equipment by KBA-Metronic, a leading German manufacturer, which can be combines with various printing systems, from inkjet industrial printers, through thermal transfer, heat-stamping to laser marking equipment. This equipment can be additionally fitted with a scanner or a camera system. Easy manipulation, high reliability, flexibility and very attractive price-performance ratio are just some of the advantages of this system, suitable for many branches, however, particularly for food-processing, pharmaceutical, automotive or packaging industry. The compact size of the KBA-Metronic UdaFORMAXX device makes it easy to use almost anywhere.

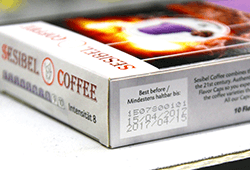

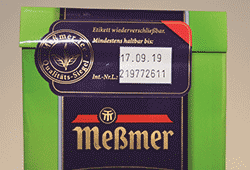

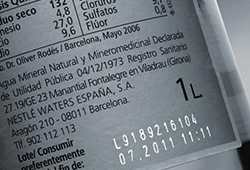

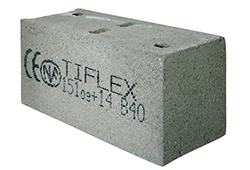

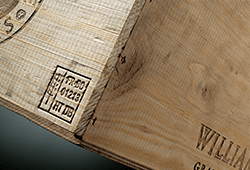

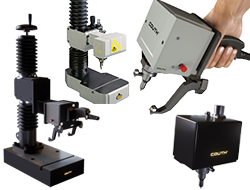

Inkjet is the most frequently used off-line marking technology. The inkjet marking equipment of the alphaJET series by KBA-Metronic, a German manufacturer, is distinguished by high reliability, excellent print quality and low operating costs. It prints graphics in high resolution, logos, barcodes, dates, batches etc. The colour touch display provides simple intuitive control using icons. The equipment can also be integrated into production lines – via Ethernet, USB or RS232 interface. The stainless chassis and IP65 protection make the alphaJET printers meet the challenging requirements of the environment. The patented solvent recovery system saves the solvent consumption and thus money. Various surfaces can be marked in relation to the used ink.

A wide range of application without compromise

The main advantages of the off-line workstations for additional marking of products outside the main production include printing of small and medium batches as required, easy settings, prompt change in the print format, product traceability, or adjusting standard packaging to the market needs. They allow printing variable data, use-by-date, prices and information about contents, barcodes, logos and other graphic symbols, as well as addressing and personalisation. They are perfect for folding boxes, cardboard, blister packs, labels, plastic cards and other stackable flat items.

Time saving, flexibility and safety

The semiautomatic off-line marking system is highly operative and saves the costs of storing packaging for various customers, various countries etc. The high sorting speed and the possibility to replenish the storage bin during production reduces downtime and labour costs. Also, the provision of product traceability and their production from product piracy with sophisticated coding and system is an inconsiderable benefit.